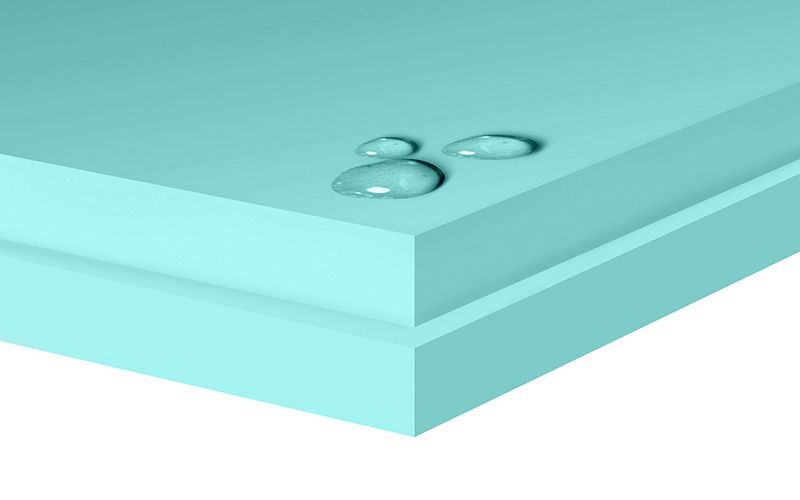

FIBRANxps 300-L is a thermal insulation board made of extruded polystyrene, having a smooth surface and edges in the shape of letter “L” to prevent the formation of thermal bridges.

Thermal insulation gives unconditional protection in humid environment and/or under extremely heavy mechanical load.

- Thermal protection of the walkable classic flat roofs

- Thermal protection with the walkable inverted flat roofs systems

- Thermal protection within the green roofs systems

- Adaptation of existing flat roofs into inverted flat roof system

- Thermal insulation and the protection of the cellar walls waterproofing

- Thermal protection of swimming pools

- Thermal protection of shop, warehouse and industrial floorings

- Thermal protection of foundation slab.

Instalation

All construction requirements should be taken into account during the application of FIBRANxps panels. FIBRANxps panels should be placed on flat and clean surfaces. They can easily be cut using a sharp knife or heated wire. Most FIBRANxps product edges are L or D shaped. The panels are usually installed in a single layer. The application of a double layer is desirable for I shaped panels, to avoid the consequent formation of thermal bridges at the joint. Thermal insulation in the inverted roof application should be installed in a single layer. No naked flames should be used during the installation of FIBRANxps extruded polystyrene panels. Whenever FIBRANxps panels are to be applied over waterproofing film on basement walls, adhesive tape should also be used. In the event of basements with a high water table, the damps proofing product should be applied to the entire wall surface. When using FIBRANxps on larger surfaces, especially on warm flat roofs,the dilation or contraction of the panels due to temperatture must be taken into account. The construction of expansion joints with stonewool is recommended in such cases. Please note: The cross sections and compositions of construction details presented in the leaflet are indicative and should be adapted wherever necessary.

All construction requirements should be taken into account during the application of FIBRANxps panels. FIBRANxps panels should be placed on flat and clean surfaces. They can easily be cut using a sharp knife or heated wire. Most FIBRANxps product edges are L or D shaped. The panels are usually installed in a single layer. The application of a double layer is desirable for I shaped panels, to avoid the consequent formation of thermal bridges at the joint. Thermal insulation in the inverted roof application should be installed in a single layer. No naked flames should be used during the installation of FIBRANxps extruded polystyrene panels. Whenever FIBRANxps panels are to be applied over waterproofing film on basement walls, adhesive tape should also be used. In the event of basements with a high water table, the damps proofing product should be applied to the entire wall surface. When using FIBRANxps on larger surfaces, especially on warm flat roofs,the dilation or contraction of the panels due to temperatture must be taken into account. The construction of expansion joints with stonewool is recommended in such cases. Please note: The cross sections and compositions of construction details presented in the leaflet are indicative and should be adapted wherever necessary.

Management and storage

FIBRANxps panels are resistant to cold weather, rain and snow, but not to long-term exposure to ultraviolet radiation from direct exposure to sunlight. Therefore the packaging must only be removed immediately prior to application of the material. In the event that the packaging is torn, the material must be protected from direct sunlight. Although FIBRANxps panels are mong the most durable materials on the market, contact with sharp objects can destroy or warp their surface. FIBRANxps dark-coloured material, they may deform due to high temperatures. FIBRANxps panels must not come into contact with organic solvents such as acetone, petrol or tar. If the panels are to be cleaned, a test of the material’s tolerance is recommended. Please consult oour technical department, if necessary. They are generally resistant to soap and detergents, but not to bleach. FIBRANxps panels are partially resistant to substrates such as begetable oils and fats, paraffin, phenol, which menas that long-term exposure to such substrates can affect the appearance or structure of their surface. FIBRANxps panels are particularly resistant to water-soluble asphalt materials, lime, cement, lime mortar, seawater, as well as thin dilute acids and silicones. A preliminary test is recommended in case of doubt.

FIBRANxps panels are resistant to cold weather, rain and snow, but not to long-term exposure to ultraviolet radiation from direct exposure to sunlight. Therefore the packaging must only be removed immediately prior to application of the material. In the event that the packaging is torn, the material must be protected from direct sunlight. Although FIBRANxps panels are mong the most durable materials on the market, contact with sharp objects can destroy or warp their surface. FIBRANxps dark-coloured material, they may deform due to high temperatures. FIBRANxps panels must not come into contact with organic solvents such as acetone, petrol or tar. If the panels are to be cleaned, a test of the material’s tolerance is recommended. Please consult oour technical department, if necessary. They are generally resistant to soap and detergents, but not to bleach. FIBRANxps panels are partially resistant to substrates such as begetable oils and fats, paraffin, phenol, which menas that long-term exposure to such substrates can affect the appearance or structure of their surface. FIBRANxps panels are particularly resistant to water-soluble asphalt materials, lime, cement, lime mortar, seawater, as well as thin dilute acids and silicones. A preliminary test is recommended in case of doubt.